Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

ST3100 FOAM WASH GUN WITH COUPLING

Description

The ST3100 food safe foam gun designed and manufactured in Germany by RM Suttner, specifically designed for foam cleaning within food processing environments. By using RM Suttner food safe foam wash guns, operators can be confident that they are complying with food safety regulations and maintaining a clean and hygienic environment in their facilities.

Technical Spec

| Inlet | 1/2" Female Swivel |

|---|---|

| Outlet | ST3100 Female |

| Max LPM | 100 LPM |

| Material | Stainless Steel |

| Bar | 60 |

| Colour | Blue |

| Max Temp °C | 150 |

| Commodity Code | 8424200000 |

| Weight | 1.40 |

| Country of Origin | Germany |

Datasheets

-

203100805 Exploded Diagram Download

203100805 Exploded Diagram Download

Need help?

Contact G&S 01768 865985

Overview

The RM Suttner ST3100 food safe foam gun

The Suttner ST3100 stainless steel guns are a range of medium pressure (60bar), high flow (100lpm) guns designed for use with foam. These are a professional gun with an external progressive valve closing system, which reduces the risk of water hammer in high flow applications. They are designed for use in foam and rinse applications within food processing environments and have impact resistant plastic housings which comply with Regulation (EC) No. 1935/2004.

RM Suttner food safe wash guns are specifically designed to meet the rigorous cleaning and hygiene standards required in the food and beverage industry. These wash guns are made from high-quality materials that are food-safe, resistant to harsh chemicals, and easy to clean. The design of the wash guns also includes features such as smooth, crevice-free surfaces and detachable parts that facilitate easy cleaning and prevent bacterial growth. The food-safe wash guns are also designed to reduce water consumption, which is essential in the food industry to minimise water waste and reduce the risk of water contamination. By using RM Suttner food safe wash guns, operators can be confident that they are complying with food safety regulations and maintaining a clean and hygienic environment in their facilities. Overall, the importance of using food safe wash guns in the food industry cannot be overstated, as they play a vital role in ensuring the safety and quality of food products while protecting the health of consumers.

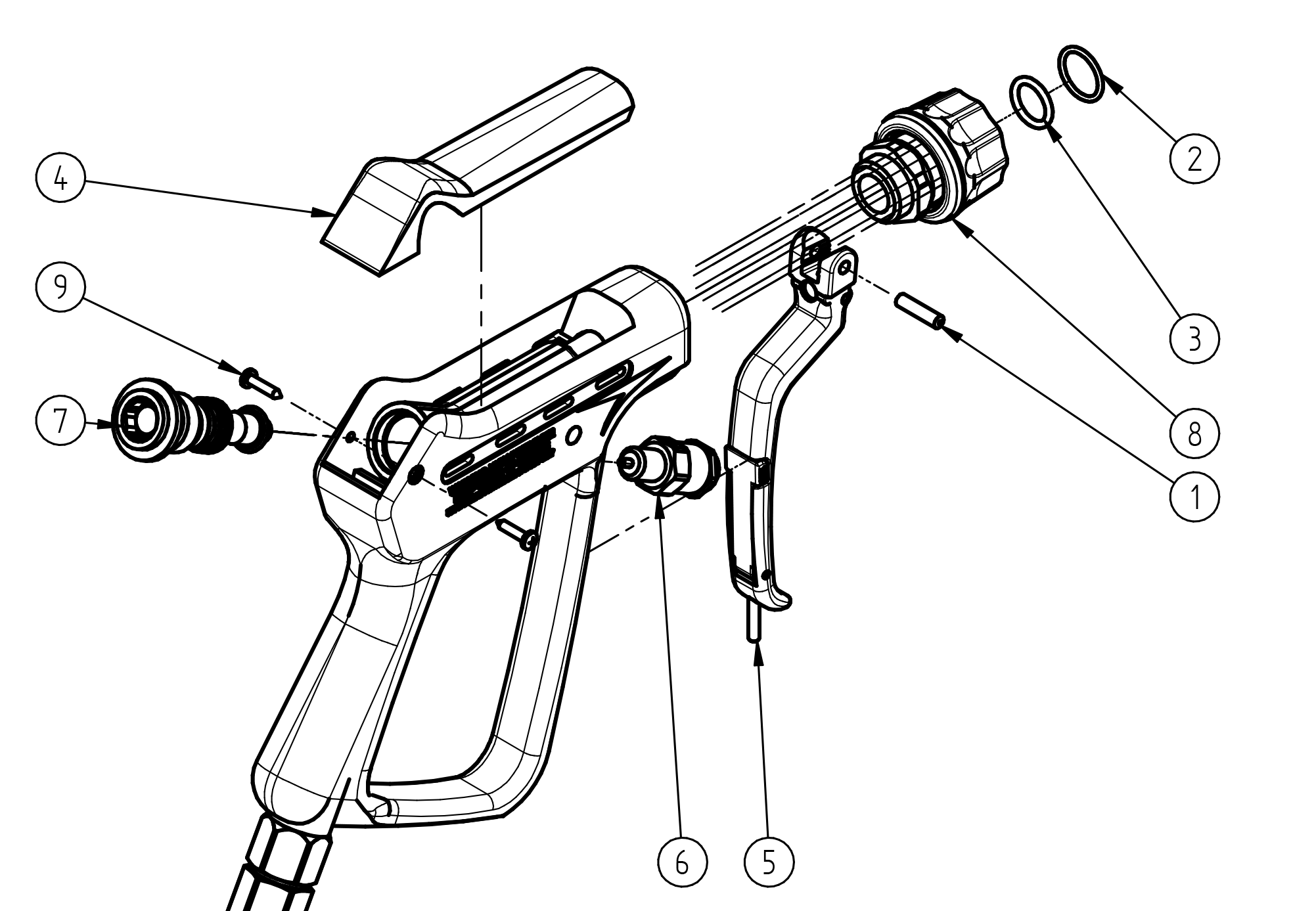

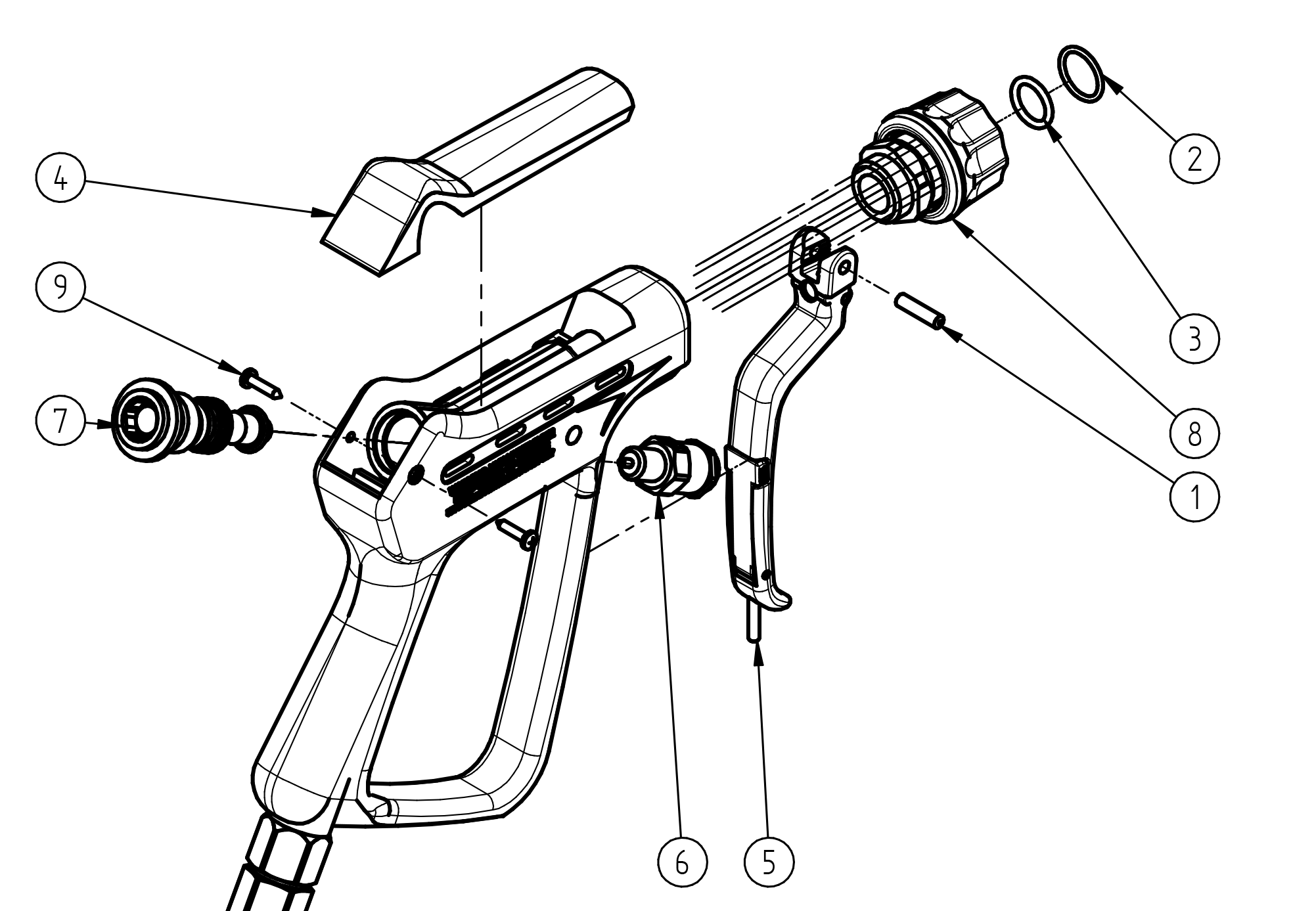

Spare Parts

- 1. Pin 5x20 SKU: 040000060

- 2. O-ring 18x2 EPDM 70Shore SKU: 050000660

- 3. O-ring 15, 1x2,7 SKU: 050000670

- 4. Plastic cap blue SKU: 020001152

- 5. Lever SKU: 203100495

- 6. Damper ST-3100 SKU: 203100485

- 7. ST-3100 Repair-kit SKU: 203100400

- 8. Coupling ST-3100 G3/8fm. blue SKU: 203100456

- 9. Repair-kit screws SKU: 900035161

Help with sizes

Foam Injector size guide.

Use the below chart to help you select the correct injector size.

Pressure

Flow

| 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | ||

| 10 |

2.2 (15) |

2.0 (15) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5 (07) |

1.4

(07) |

1.3

(05) |

|||||||||||||||||

| 11 |

2.2 (15) |

2.0 (15) |

1.9 (13) |

1.8 (13) |

1.7

(10) |

1.6

(075) |

1.5 (07) |

1.4

(07) |

1.3

(05) |

||||||||||||||||

| 12 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9 (13) |

1.8 (13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

1.3 (05) |

|||||||||||||||

| 13 |

2.2 (15) |

2.1 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

14 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

|||||||

| 15 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4 (07) |

||||||||||||||||

| 16 |

2.2 (15) |

2.1 (15) |

2.0

(15) |

1.9 (13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

||||||||||||||||||

| 18 |

2.3 (20) |

2.2 (15) |

2.1

(15) |

2.0

(15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6 (075) |

|||||||||||||||||

| 19 |

2.3 (20) |

2.3 (20) |

2.2 (15) |

2.1

(15) |

2.0

(15) |

1.9 (13) |

1.8

(13) |

1.7

(10) |

|||||||||||||||||

| 21 |

1.9

(13) |

1.8

(13) |

1.7

(10) |

||||||||||||||||||||||

You will need to know the flow rate and pressure of the pressure washer or system that the injector is to be installed.

Firstly select the closest flow rate (round up if required)

Then move right across the chart until you are at the closest pressure column.

The top number (1.6) is the injector size.

For foam injectors not using compressed air the number in brackets underneath is the correct ST75 foam lance size required.

| Alternative | ||||

| Injector Size | Injector Part No | ST75 Size | ST75 Foam Lance | ST72 Foam Lance |

| 1.3 | 200160500 | 05 | 200075576 | 200072633 |

| 1.4 | 200160505 | 07 | 200075572 | 200072633 |

| 1.5 | 200160510 | 07 | 200075572 | 200072633 |

| 1.6 | 200160515 | 075 | 200075572 | 200072633 |

| 1.7 | 200160520 | 10 | 200075573 | 200072625 |

| 1.8 | 200160525 | 13 | 200075578 | 200072625 |

| 1.9 | 200160530 | 13 | 200075578 | 200072625 |

| 2.0 | 200160535 | 15 | 200075579 | 200072629 |

| 2.1 | 200160540 | 15 | 200075579 | 200072629 |

| 2.2 | 200160545 | 15 | 200075579 | 200072629 |

| 2.3 | 200160550 | 20 | Please Contact | 200072629 |