Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

ST-167 350 BAR FOAM INJECTOR -1.9mm

Description

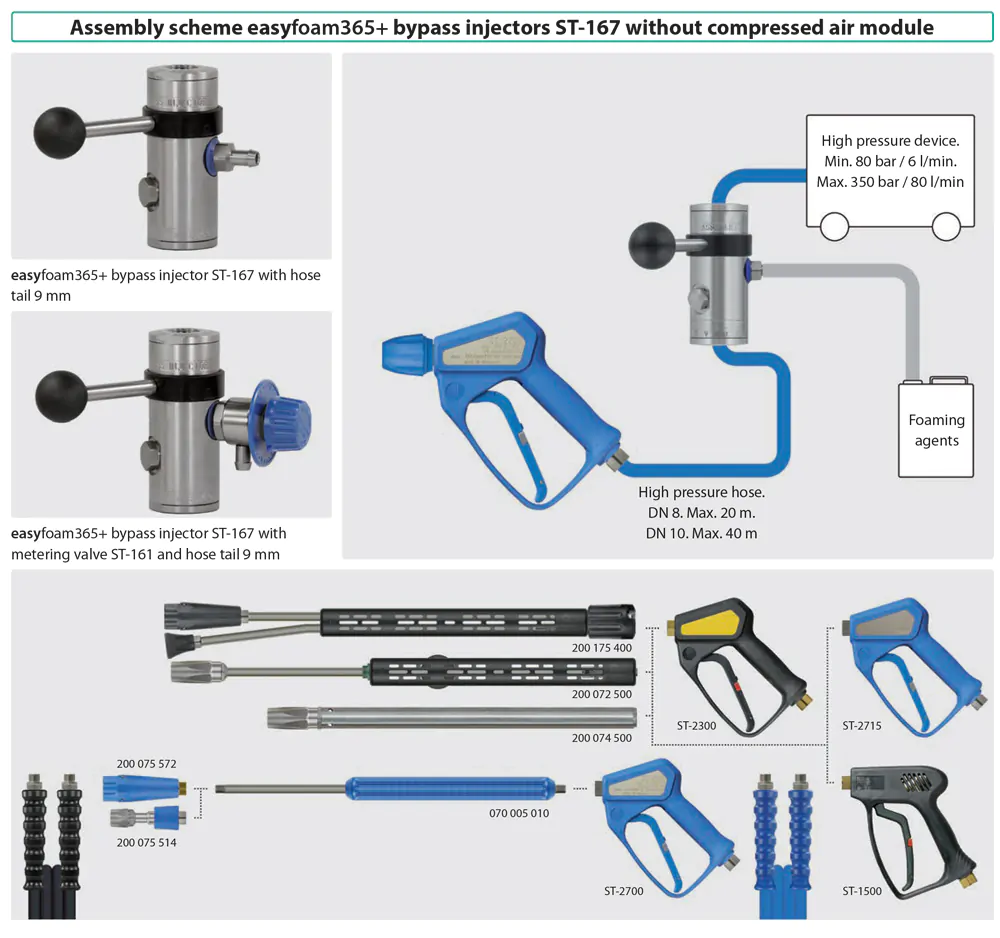

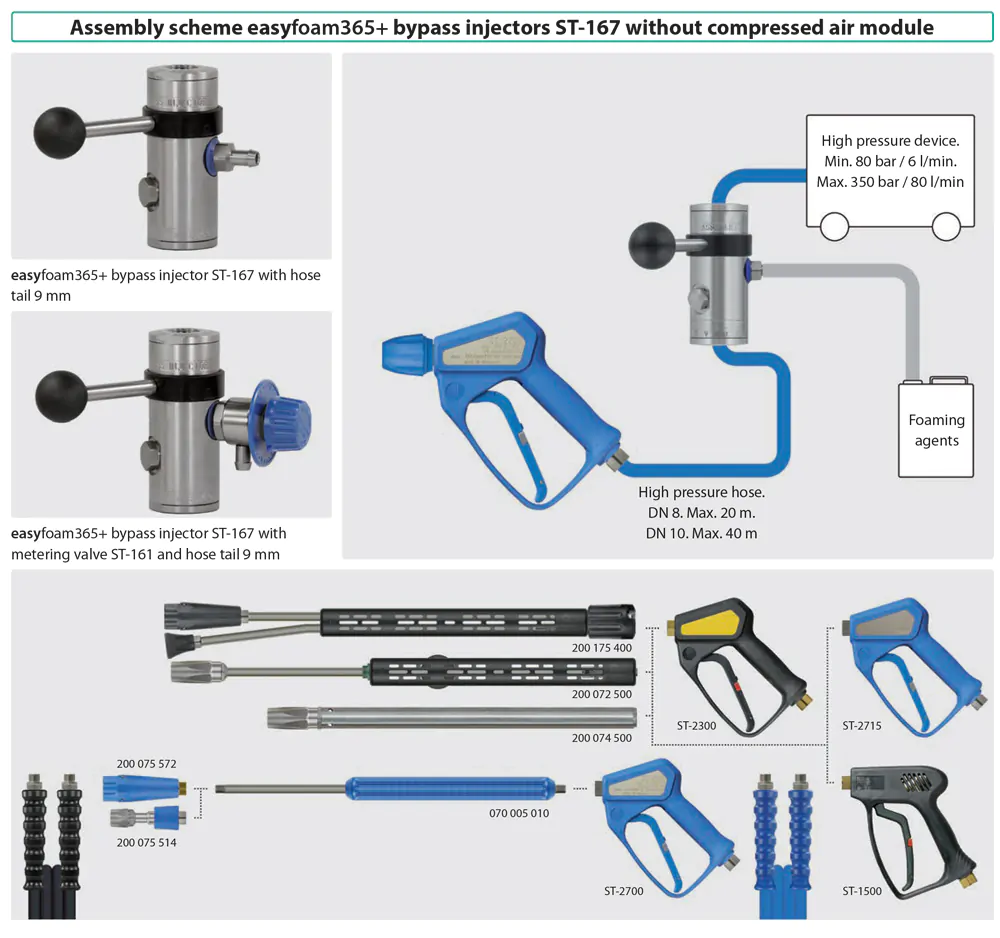

The ST167 foam injector with a maximum pressure rating of 350 bar enables the user to easily switch between rinse and foam. When combined with a foam lance (ST-72, ST-74, or ST-75) and an adjustable or triple nozzle, the easyfoam365+ injector ST-167 can draw in chemicals via its integrated stainless-steel check valve. The selected nozzle determines whether the chemical is sprayed or foamed.

Technical Spec

| Inlet | 1/2" Female |

|---|---|

| Outlet | 1/2" Female |

| Max LPM | 80 LPM |

| Material | Stainless Steel |

| Bar | 350 |

| Max Temp °C | 100 |

| Nozzle Size | 1.9mm |

| DN Internal Diameter | 9mm |

| Commodity Code | 8413810090 |

| Weight | 1.11 |

| Country of Origin | Germany |

Need help?

Contact G&S 01768 865985

Overview

ST167 Foam injector 350 bar

These injectors are made entirely of stainless steel, feature two cross-section openings (50 mm² each) to ensure smooth operation without pressure loss during washing and rinsing. This allows the injector to remain permanently installed in the high-pressure line, even when handling large water volumes, such as in agriculture or the food industry.

The cleaning performance remains unaffected during both washing and rinsing. A lever enables easy switching between cleaning/rinsing mode and injector operation.

In cleaning mode, two boreholes direct high-pressure water parallel to the injector (bypass mode).

In injector mode, the available water volume is guided through the injection area.

When combined with a foam lance (ST-72, ST-74, or ST-75) and an adjustable or triple nozzle, the easyfoam365+ injector ST-167 can draw in chemicals via its integrated stainless-steel check valve. The selected nozzle determines whether the chemical is sprayed or foamed.

Foaming provides excellent coverage and extended dwell time, making treated surfaces easily visible.

The easyfoam365+ injector, available in nozzle sizes from 1.2 to 2.8 mm, meets the demands of professional cleaning applications. Chemical dosing is adjusted using one of the 10 interchangeable nozzle inserts included in the package. Alternatively, versions with the ST161 metering valve are avilable which allows the user to easily adjust the amount of chemical entering the water stream by turning the valve.

The chemical connection, featuring an integrated check valve and a nozzle insert intake, includes a 9 mm hose tail for suction hoses, ensuring compatibility with highly viscous fluids.

For easy installation, flow direction indicators are clearly marked.

Help with sizes

Foam Injector size guide.

Use the below chart to help you select the correct injector size.

Pressure

Flow

| 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | ||

| 10 |

2.2 (15) |

2.0 (15) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5 (07) |

1.4

(07) |

1.3

(05) |

|||||||||||||||||

| 11 |

2.2 (15) |

2.0 (15) |

1.9 (13) |

1.8 (13) |

1.7

(10) |

1.6

(075) |

1.5 (07) |

1.4

(07) |

1.3

(05) |

||||||||||||||||

| 12 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9 (13) |

1.8 (13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

1.3 (05) |

|||||||||||||||

| 13 |

2.2 (15) |

2.1 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

14 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

|||||||

| 15 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4 (07) |

||||||||||||||||

| 16 |

2.2 (15) |

2.1 (15) |

2.0

(15) |

1.9 (13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

||||||||||||||||||

| 18 |

2.3 (20) |

2.2 (15) |

2.1

(15) |

2.0

(15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6 (075) |

|||||||||||||||||

| 19 |

2.3 (20) |

2.3 (20) |

2.2 (15) |

2.1

(15) |

2.0

(15) |

1.9 (13) |

1.8

(13) |

1.7

(10) |

|||||||||||||||||

| 21 |

1.9

(13) |

1.8

(13) |

1.7

(10) |

||||||||||||||||||||||

You will need to know the flow rate and pressure of the pressure washer or system that the injector is to be installed.

Firstly select the closest flow rate (round up if required)

Then move right across the chart until you are at the closest pressure column.

The top number (1.6) is the injector size.

For foam injectors not using compressed air the number in brackets underneath is the correct ST75 foam lance size required.

| Alternative | ||||

| Injector Size | Injector Part No | ST75 Size | ST75 Foam Lance | ST72 Foam Lance |

| 1.3 | 200160500 | 05 | 200075576 | 200072633 |

| 1.4 | 200160505 | 07 | 200075572 | 200072633 |

| 1.5 | 200160510 | 07 | 200075572 | 200072633 |

| 1.6 | 200160515 | 075 | 200075572 | 200072633 |

| 1.7 | 200160520 | 10 | 200075573 | 200072625 |

| 1.8 | 200160525 | 13 | 200075578 | 200072625 |

| 1.9 | 200160530 | 13 | 200075578 | 200072625 |

| 2.0 | 200160535 | 15 | 200075579 | 200072629 |

| 2.1 | 200160540 | 15 | 200075579 | 200072629 |

| 2.2 | 200160545 | 15 | 200075579 | 200072629 |

| 2.3 | 200160550 | 20 | Please Contact | 200072629 |