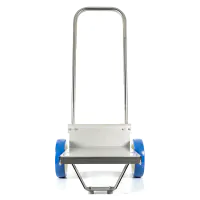

Non Marking Wheels

Non-marking wheels are crucial in the food industry because they help maintain strict hygiene and cleanliness standards required in food processing and handling environments. Unlike traditional wheels, non-marking wheels are made from materials such as polyurethane or thermoplastic rubber that do not leave scuff marks, streaks, or debris on floors. This is essential in facilities where contamination risks must be minimised, and surfaces must remain spotless for both safety and compliance with health regulations. Additionally, non-marking wheels reduce the need for frequent cleaning and maintenance of floors, enhancing operational efficiency and protecting sensitive flooring materials commonly used in food-grade environments.

Made from 316 Stainless Steel

The TecPro mobile trolley for industrial cleaning, specifically designed for the food industry and manufactured in the UK, is built from 316 stainless steel to meet the strict regulatory requirements of food safety and hygiene. 316 stainless steel is crucial in these settings because of its exceptional resistance to corrosion, particularly in environments exposed to moisture, food, and harsh cleaning chemicals. This level of durability ensures that the trolley can endure frequent cleaning cycles without compromising the integrity of the equipment or contaminating the environment. In food production and processing facilities, where hygiene is critical, 316 stainless steel helps prevent the growth of bacteria and contaminants, meeting both food safety regulations and industry standards. Its resistance to pitting and crevice corrosion further ensures that the trolley remains safe, durable, and compliant with the stringent hygiene protocols required by regulatory bodies such as the FDA and EU food safety standards. This makes it an ideal choice for maintaining cleanliness and operational efficiency in food industry environments.