Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

RM 544 STAINLESS STEEL AUTOMATIC HOSE REEL UP TO 30M

Description

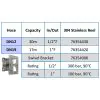

Type 03, suitable for following hoses:

22mm hose = 30m capacity

28mm hose = 22m capacity

34mm hose = 17m capacity

For DN 12 hose

Technical Spec

| Inlet | 1/2" Female |

|---|---|

| Outlet | 1/2" Female |

| Material | Stainless Steel |

| Bar | 300 |

| Max Temp °C | 90 |

| DN Internal Diameter | 12mm |

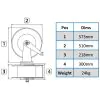

| Dimensions | - Height 573mm - Width 300mm - Depth 510mm - Reel Width 218mm |

| Commodity Code | 8479899790 |

| Weight | 27.40 |

Datasheets

-

ECODORA REELS Download

ECODORA REELS Download

Need help?

Contact G&S 01768 865985

Overview

High-Quality Construction

Durable Materials: Made from V2A / AISI 304 Stainless Steel, the hose reels are built to withstand the rigors of demanding environments. They offer exceptional resistance to corrosion and wear, ensuring long-lasting performance.

Automatic Spring-Driven Mechanism: The advanced spring-driven mechanism ensures reliable and efficient hose retraction, making operations smoother and more convenient.

Versatile Applications

Multiple Mounting Options: The hose reels are designed for easy installation on walls, ceilings, or vehicles. Optional wall brackets enable quick and secure mounting, with both fixed and swiveling bracket options available to suit different needs.

Wide Medium Compatibility: Suitable for various mediums, including water, cleaning detergents, air, oils, and greases, these hose reels are versatile and adaptable to different industrial requirements.

Safety and Compliance

ATEX Certified: Compliant with directive 94/9/EG (ATEX 95/100), the hose reels are approved for use in explosive zones 1 and 2 (gas) and 21 and 22 (dust). This certification ensures they can be safely used in mining and other explosion-proof areas.

Temperature Rating: Suitable for environments up to 135°C, the hose reels meet the ATEX II 2/GD c (T4) standards, providing reliable performance in high-temperature applications.

Convenient Features

Traction Release Mechanism: A quick pull on the hose releases the locking mechanism, allowing for easy and efficient hose retraction.

Stainless Steel Swivel: Each hose reel is equipped with a Stainless Steel ST-322 swivel, ensuring smooth and leak-free operation.

Food Industry Industrial cleaning equipment

For more information regarding equipment we can supply for industrial cleaning of food processing environments click below.

These Stainless Steel Automatic Hose Reels are ideal for:

Service Stations: Efficiently manage hoses for fueling and cleaning.

Garages: Keep hoses organised and easily accessible.

Agriculture: Durable enough to withstand the harsh conditions of agricultural environments.

Building Industries: Reliable for use in construction sites and maintenance.

Food Industry: Using stainless steel equipment helps in complying with industry standards and regulations related to food safety and hygiene.

Using a stainless steel automatic hose reel in the food industry is important for several reasons:

1. Hygiene and Sanitation

Corrosion Resistance: Stainless steel is highly resistant to rust and corrosion, which is crucial in environments where the hose reel will be exposed to water, cleaning agents, and food particles.

Easy to Clean: Stainless steel surfaces are smooth and non-porous, making them easier to clean and sanitise. This helps in preventing the buildup of bacteria and other contaminants, ensuring that hygiene standards are maintained.

Food Safety Compliance: Stainless steel is compliant with food safety regulations. Using materials that meet these standards helps in preventing contamination and ensuring that the food products are safe for consumption.

2. Durability and Longevity

Robust Construction: Stainless steel is known for its strength and durability. Hose reels made from stainless steel can withstand the harsh conditions of a food processing environment, including constant exposure to water, steam, and cleaning chemicals.

Long-lasting Performance: The durability of stainless steel means that the hose reels will have a longer service life, reducing the need for frequent replacements and maintenance.

3. Operational Efficiency

Automatic Retraction: Automatic hose reels improve efficiency by quickly and neatly retracting the hose after use. This reduces the time spent on manual winding and keeps the workspace organised.

Space Saving: Automatic hose reels help in efficiently managing hose storage, saving valuable floor space in a busy food processing area.

Reduced Trip Hazards: By keeping the hoses properly stored and off the floor, automatic hose reels help in reducing trip hazards, contributing to a safer working environment.

4. Cost-effectiveness

Lower Maintenance Costs: The durability and corrosion resistance of stainless steel mean lower maintenance costs over time. There is less need for repairs or replacements, leading to cost savings.

Improved Productivity: The ease of use and efficiency of automatic hose reels can lead to improved productivity, as employees can focus more on their core tasks rather than managing hoses.

5. Professional Appearance

Clean and Tidy Work Environment: A well-organised workspace with neatly stored hoses reflects professionalism and a commitment to high standards. This is important for audits, inspections, and the overall image of the food processing facility.

6. Compliance with Industry Standards

Meeting Regulatory Requirements: Using stainless steel equipment helps in complying with industry standards and regulations related to food safety and hygiene. This is essential for maintaining certifications and avoiding penalties.

In summary, stainless steel automatic hose reels are vital in the food industry due to their ability to maintain high hygiene standards, durability, operational efficiency, cost-effectiveness, professional appearance, and compliance with regulatory requirements. These benefits collectively contribute to a safer, more efficient, and reliable food processing environment.