Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

ST74 FOAM LANCE WITH AIR INJECTOR 2.1 mm

Description

The ST74 foam lance is often used in a variety of industries, such as food, beverage, and agriculture, to clean surfaces such as floors, walls, and equipment. The foam lance is particularly effective in cleaning surfaces that are difficult to reach or clean thoroughly with traditional cleaning methods.

Technical Spec

| Inlet | 1/4" Female |

|---|---|

| Material | Stainless Steel |

| Angle in Degrees° | 40 |

| Length | 530mm |

| Max Temp °C | 90 |

| Nozzle Size | 2.1mm |

| Weight | 0.79 |

| Country of Origin | Germany |

Datasheets

-

200074505 Spare Parts Download

200074505 Spare Parts Download

Need help?

Contact G&S 01768 865985

Overview

ST74 Foam Lance

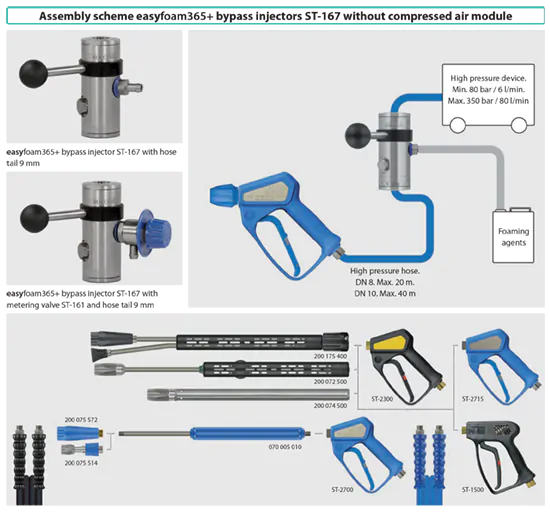

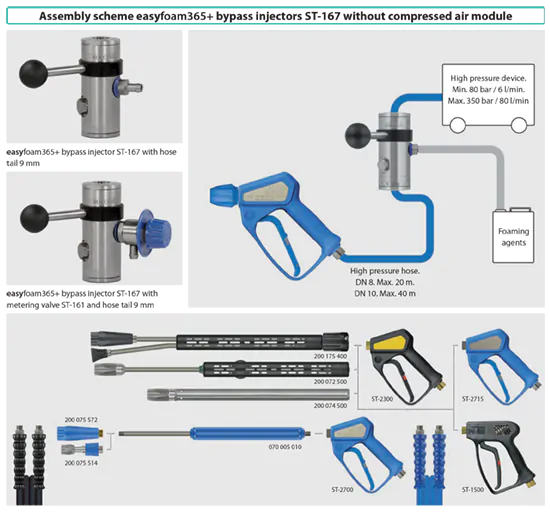

The ST74 foam lance is a tool used in industrial cleaning to apply cleaning agents or detergents in the form of a thick foam. The foam is then applied to the surface to be cleaned, allowing the cleaning solution to penetrate and loosen dirt, grime, and other contaminants. The foam also helps to reduce the amount of cleaning solution needed and minimizes the amount of water required for cleaning. This makes the cleaning process more efficient and cost-effective, while also reducing the impact on the environment. This lance is available with 2.1mm and 2.3mm nozzle sizes, the 2.1mm version is for up to 15 lpm and the 2.3mm version is for up to 20 lpm. There are a selection of injectors that can be used with this product, to ensure you select the correct injector size for the system you are building please use our interactive chart below. All you require are the flow and pressure ratings of the system you are installing the equipment onto.

Open plant cleaning using foam

Open plant cleaning enures all machines and surfaces in a food processing environment are thoroughly cleaned and disinfected. As a producer or processor of foods it is critical to maintain constant hygiene standards. This is done by applying a clingy foam using specialist equipment such as a foam injector and foam lance. Due to it's internal 12mm diameter our Hygiene Ultra 40 hose is ideal for a system that generates foam using a compressed air module at the injector. This diamteter enables the foam to travel down the hose without collapsing back into a liquid state, the foam exits via a specialist foam lance or wash gun. Another major benefit of using our exclusive Hygiene Ultra 40 hose as part of a cleaning system is it's antimicrobial top layer. The properties of this layer will stop the growth of micro-organisms, dramatically lowering the risk of cross contamination.

G&S have a range of equipment dedicated to cleaning food processing environments. Take a look at our Food Industry page for more information.

Help with sizes

Foam Injector size guide.

Use the below chart to help you select the correct injector size.

Pressure

Flow

| 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | ||

| 10 |

2.2 (15) |

2.0 (15) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5 (07) |

1.4

(07) |

1.3

(05) |

|||||||||||||||||

| 11 |

2.2 (15) |

2.0 (15) |

1.9 (13) |

1.8 (13) |

1.7

(10) |

1.6

(075) |

1.5 (07) |

1.4

(07) |

1.3

(05) |

||||||||||||||||

| 12 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9 (13) |

1.8 (13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

1.3 (05) |

|||||||||||||||

| 13 |

2.2 (15) |

2.1 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

14 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4

(07) |

|||||||

| 15 |

2.2 (15) |

2.1 (15) |

2.0 (15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

1.5

(07) |

1.4 (07) |

||||||||||||||||

| 16 |

2.2 (15) |

2.1 (15) |

2.0

(15) |

1.9 (13) |

1.8

(13) |

1.7

(10) |

1.6

(075) |

||||||||||||||||||

| 18 |

2.3 (20) |

2.2 (15) |

2.1

(15) |

2.0

(15) |

1.9

(13) |

1.8

(13) |

1.7

(10) |

1.6 (075) |

|||||||||||||||||

| 19 |

2.3 (20) |

2.3 (20) |

2.2 (15) |

2.1

(15) |

2.0

(15) |

1.9 (13) |

1.8

(13) |

1.7

(10) |

|||||||||||||||||

| 21 |

1.9

(13) |

1.8

(13) |

1.7

(10) |

||||||||||||||||||||||

You will need to know the flow rate and pressure of the pressure washer or system that the injector is to be installed.

Firstly select the closest flow rate (round up if required)

Then move right across the chart until you are at the closest pressure column.

The top number (1.6) is the injector size.

For foam injectors not using compressed air the number in brackets underneath is the correct ST75 foam lance size required.

| Alternative | ||||

| Injector Size | Injector Part No | ST75 Size | ST75 Foam Lance | ST72 Foam Lance |

| 1.3 | 200160500 | 05 | 200075576 | 200072633 |

| 1.4 | 200160505 | 07 | 200075572 | 200072633 |

| 1.5 | 200160510 | 07 | 200075572 | 200072633 |

| 1.6 | 200160515 | 075 | 200075572 | 200072633 |

| 1.7 | 200160520 | 10 | 200075573 | 200072625 |

| 1.8 | 200160525 | 13 | 200075578 | 200072625 |

| 1.9 | 200160530 | 13 | 200075578 | 200072625 |

| 2.0 | 200160535 | 15 | 200075579 | 200072629 |

| 2.1 | 200160540 | 15 | 200075579 | 200072629 |

| 2.2 | 200160545 | 15 | 200075579 | 200072629 |

| 2.3 | 200160550 | 20 | Please Contact | 200072629 |