Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

SPRAYING SYSTEMS HIGH PRESSURE NOZZLE, 1/8" MEG, 1509

Description

Technical Spec

| Inlet | 1/8" Male |

|---|---|

| Material | 303 Stainless Steel |

| Angle in Degrees° | 15 |

| Nozzle Diameter | 09 |

| Commodity Code | 8424200000 |

| Weight | 0.01 |

| Country of Origin | China |

Datasheets

-

Nozzle Size Chart Download

Nozzle Size Chart Download

Need help?

Contact G&S 01768 865985

Overview

Spraying Systems nozzles

Spraying Systems nozzles are essential components in a wide range of industrial and agricultural applications, where liquids need to be precisely sprayed onto a surface or a target area. These nozzles are designed to create a uniform and consistent spray pattern, with droplet sizes and spray angles tailored to specific needs. Depending on the application, spraying systems nozzles can be made from a variety of materials, the nozzles we supply are stainless steel or flat fan designed for high or low flow rates, high or low pressures, and different types of spray patterns, such as flat fan, full cone, hollow cone, or mist. The proper selection and use of Spraying Systems nozzles can have a significant impact on the effectiveness, efficiency, and quality of a spraying process.

The quality of Spraying Systems nozzles is critical to the success of any spraying process. A well-designed and well-manufactured nozzle can provide precise and consistent spray patterns, uniform droplet sizes, and high spray efficiency. On the other hand, a poorly designed or low-quality nozzle can result in uneven spray patterns, clogging, dripping, or excessive overspray, which can lead to waste, reduced efficacy, and environmental pollution. To ensure the quality of spraying systems nozzles, manufacturers use advanced technologies and materials, such as computer-aided design, 3D printing, laser cutting, and high-grade alloys, and conduct rigorous testing and quality control procedures, such as flow rate testing, pressure testing, drop size analysis, and chemical resistance testing. In addition, users can optimize the performance and lifespan of spraying systems nozzles by following the manufacturer's recommendations on nozzle selection, maintenance, and replacement, and by monitoring the spraying process for any signs of nozzle wear or damage.

How efficient are your nozzles ?

Worn nozzles can result in reduced efficiency and cost extra in the long run, Check your nozzles regularly. Click the image below to the Spraying Systems liquid savings calculator, which will highlight potential losses due to worn poor quality nozzles.

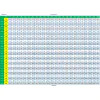

Help with sizes

Interactive Nozzle selection chart.

If you know the flow and pressure of the machine you are working on, simply select your pressure along the top of the chart and move down until you reach your nearest flow rate. Click the box which has your flow rate and this will give you your required nozzle size.