Don't have an account?

Creating an account has many benefits: check out faster, keep more than one address, track orders and more.

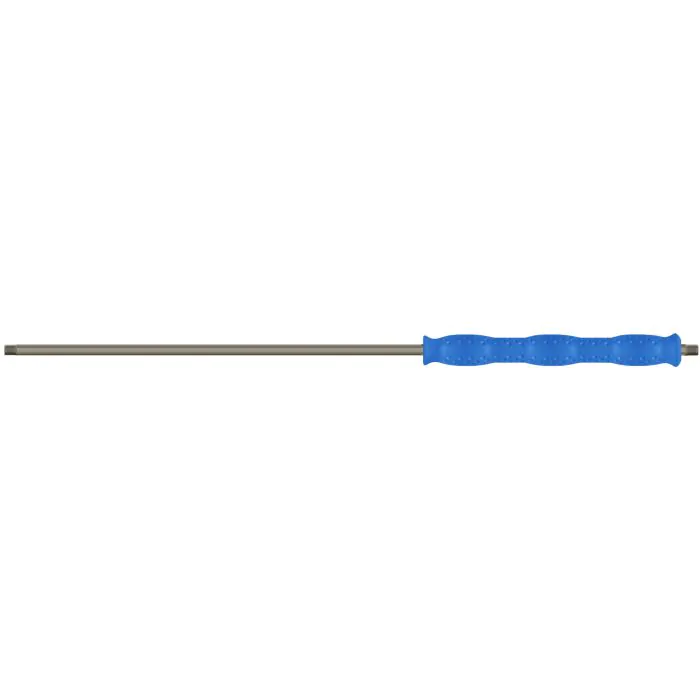

ST29 LANCE WITH INSULATION, 900mm, 1/4"M, BLUE

Description

The Suttner HACCP compliant ST129 lances are made from stainless steel and durable plastic, to ensure longevity and resistance to wear and tear. The lance is designed with user comfort in mind and features an ergonomic grip and lightweight construction, making it easy to handle during extended cleaning tasks. The ST129 lance is engineered to handle high-pressure water flow. It can withstand the force and pressure generated by pressure washers.

Technical Spec

| Inlet | 1/4" Male |

|---|---|

| Outlet | 1/4" Male |

| Material | Stainless Steel |

| Bar | 400 |

| Colour | Blue |

| Length | 900mm |

| Max Temp °C | 150 |

| Commodity Code | 8424200000 |

| Weight | 0.59 |

| Country of Origin | China |

Need help?

Contact G&S 01768 865985

Overview

HACCP colour coded Lances to minimise the risk of cross-contamination.

HACCP (Hazard Analysis and Critical Control Points) colour coding in the food industry refers to a system where different colours are used to designate specific areas, tools, equipment, or products in a food handling environment. The purpose of HACCP colour coding is to minimise the risk of cross-contamination and foodborne illnesses by clearly segregating different types of materials and preventing them from coming into contact with each other.

Here are some common examples of HACCP colour coding:

Red: Red is often used to designate areas or equipment that pose a high-risk of contamination, such as raw meat processing areas or utensils used for handling raw meat. It serves as a warning to handle these items with caution.

Blue: Blue is commonly used for areas where seafood is processed or stored. It helps to distinguish seafood processing from other food handling activities.

Green: Green is typically used for fresh produce areas or utensils used for handling fruits and vegetables. It helps to prevent contamination between raw produce and other food items.

Yellow: Yellow may be used for areas or equipment designated for allergen handling. It alerts staff to the presence of allergens and reminds them to take appropriate precautions to prevent cross-contact.

White: White is often used for general food processing areas or equipment that can be easily cleaned and sanitized. It signifies that the area or equipment is clean and ready for use.

HACCP colour coding is important for several reasons:

Preventing cross-contamination: By clearly segregating different types of materials and products, HACCP colour coding helps to prevent cross-contamination between raw and cooked foods, allergens, and other potential contaminants.

Improving food safety: By reducing the risk of cross-contamination, HACCP colour coding helps to improve overall food safety and reduce the likelihood of foodborne illnesses.

Enhancing efficiency: HACCP colour coding makes it easier for staff to identify and locate specific items or areas, which can help to streamline operations and improve efficiency in food handling processes.

Compliance with regulations: Many food safety regulations and standards require the implementation of HACCP principles, including colour coding, to ensure the safety and quality of food products.

Overall, HACCP color coding is an important tool in the food industry for maintaining food safety, preventing contamination, and ensuring compliance with regulations.